Skid Resistance Specifications in UK Road Surfacing

NOTICE OF DISCLAIMER:

No liability is accepted for errors or inaccuracies in any of information contained on this website. All views or opinions expressed are personal to the author who does not purport to speak for, or represent, any professional body or organisation. Reliance should not be placed on any material contained in this webpage without first seeking and obtaining further professional advice.

Introduction

Currently in the UK the skid

resistance for surface course materials is traditionally specified by stipulating

a minimum Polished Stone Value (PSV) of the coarse aggregate or pre-coated

chippings. There are question marks on whether the high reliance on PSV provides

the safest surface. Thin Surface Course Systems (TSCS) to Clause 942 are now

the most common surfacing materials. These products have their origins in the

German Stone Mastic Asphalt (SMA) and were originally modified for British

specifications & conditions. Some years ago Scotland digressed from the

rest of the UK’s approach to PSV and introduced a new way of specifying skid

resistance. In 2020 Wales adopted a similar approach to Scotland.

Skid Resistance Management

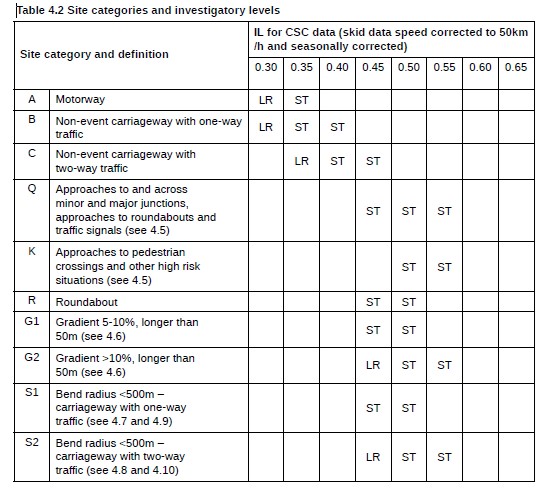

The longer-term in-service skid resistance is routinely measured using the SCRIM machine. The characteristic SCRIM coefficient or CSC is the measured SFC factored by the Index of SCRIM and corrected for speed and seasonal effects, where applicable. Management of skid resistance on UK motorway and all-purpose trunk roads is controlled by DMRB CS 228 (formerly HD 28), and determines the investigatory level (IL), (note this is not an intervention level) for different site categories and traffic levels. Table 4.2, copied below, assigns an IL for each part of the network.

Aggregate PSV’s for Surface Course

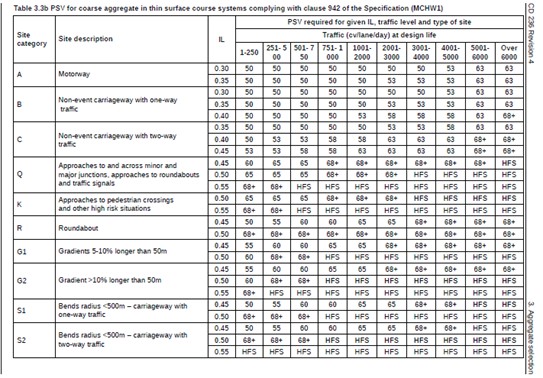

The most common sizes for TSCS aggregates currently are 14mm & 10mm, with lesser requirements for 6mm. Permitted Bituminous Surface Course Materials for motorways and trunk roads in England & Northern Ireland, are contained in DMRB CD 236 ((formerly HD 36). The appropriate PSV for the coarse aggregate in the TSCS must be selected from Table 3.3b of this document, copied below.

Surfacing options for outside of motorway & trunk roads are usually governed by the requirements of the specific local authority (LA). Most of the LA’s will use CD 236 for guidance when preparing their surfacing requirements.

PSV is typically the main property used when specifying surface course aggregate in England & Northern Ireland. There is a misconception that high PSV equates to good skid resistance. This is frequently not the case. For natural aggregates, high PSV is gained at the expense of other aggregate properties such as strength, abrasion and durability. (Woodward, WDH, Woodside, AR and Jellie, J.H). Research by Woodward et al suggests that the standard PSV test is simply a ranking tool that offers limited prediction of the complex development of skid resistance during the life of modern asphalt materials. This research has shown that the standard PSV test should not be considered as a measure of an ultimate state of polish, nor should it be the sole basis of surfacing aggregate selection (Woodward, WDH, Woodside, AR and Jellie, J.H). In the writer’s opinion, CD 236 is a useful guide to PSV requirements, but other properties such as strength, abrasion & durability should be factored in.

Scotland & Wales Deviation from CD 236

Scotland has digressed from the rest of the UK and some years ago introduced their own TS2010 specification for TSCS.https://www.transport.gov.scot/media/43503/tsia-35-18-combined.pdf

The skid resistance of TS2010 surface course is controlled by a performance-based specification (TSIA No 35, 2018). The latter involves measuring the early-life skid resistance of new materials using a braked-wheel fixed slip device, known as the Grip Tester. Similar to the rest of the UK, the longer-term in-service skid resistance is measured using the sideway-force coefficient routine investigation machine (SCRIM). TS2010 does not stipulate a minimum PSV value, but the PSV must be stated. With the introduction of the performance requirement for skid resistance within TS2010, and the adoption of a PSV Declared value in the contract, the opportunity to adopt and verify the satisfactory performance of aggregates with variant PSVs has been created.

Transport Scotland

commissioned WSP to undertake a study to gain a better understanding of the

relationship between TS2010 surface course materials and the skid resistance

provided by the materials. The overall aim of the study was to evaluate the

current procedure for providing appropriate levels of skid resistance on the

trunk road network, and to assess whether any changes were required. Their

report was published in July 2020.

https://www.transport.gov.scot/media/48066/providing-appropriate-levels-of-skid-resistance.pdf

Some of the key findings were:

- no significant difference was observed in skid resistance performance of individual TS2010 mixtures when laid on different Site Classes;

- the current approval system for classifying

TS2010 in terms of friction performance is working well;

- the relationship between aggregate PSV and CSC

is complex, with some lower PSV aggregates outperforming higher PSV aggregates;

there appears to be little benefit in specifying natural aggregates with a PSV

68+, as they do not perform any better than aggregates in the PSV 65-67 range.

- the overall CSC performance of TS2010 shows that

the top performing mixtures will broadly achieve 0.5 IL.

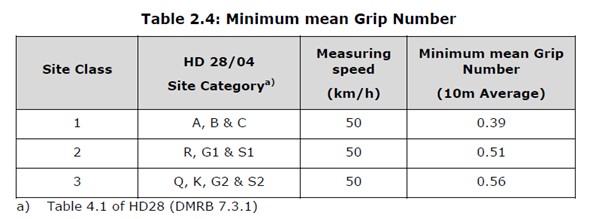

The early life skid resistance requirements for a TS2010 surface are set out in Table 2.4 shown hereunder.

By way of example, let us consider Site Class 3, say category Q, approach to a roundabout. Let’s say the traffic volumes are 600 cv/lane/day and the IL has been set at 0.5. This category of site is considered to have a high risk of skidding. From Table 3.3b of CD 236 , Clause 942 material in England would currently require a PSV65 coarse aggregate.

The current Scottish practice is that TS2010 mixtures are given Site Class approval based on a combination of Grip Tester and CSC measurements. The former is used in the material’s early life, which can be up to one year, thereafter the approval is based on CSC performance. The performance of TS2010 materials on different site classes is reviewed on an annual basis. Depending on the in-service performance of each material, authorisation for use on site classes is reviewed, i.e. a higher or lower Site Class can be approved based on CSC performance.

There is therefore scope in Scotland to design an SSA TS2010 mixture (or blend) which meets the requirements of Table 2.4 above & verified using the prTAIT procedure and ongoing CSC measurements. The Notes for Guidance document issued with TS2010 suggests that an SMA 10 would be appropriate for this site category. Research has indicated that smaller nominal size SMA’s should be used for higher stressed sites as they will provide higher skidding resistance & be more durable. This should increase the amount of SMA 10 used with a corresponding decrease in SMA 14.

In 2020 the Welsh Government issued a new specification for SMA, Procedure & Advice Guidance (PAG) 112/20. The Scottish TS2010 was used as the foundation for this document and follows the same principles. There will be opportunities for lower PSV aggregates with good properties to be included in situations from which they would have been precluded heretofore.

Summary

The traditional practice in the UK for specifying skid resistance in TSCS has been to stipulate a minimum PSV value for the coarse aggregate. Many experiences practitioners believe that this system is flawed and that an over reliance has been placed on PSV, without properly considering the other aggregate properties and local knowledge of their historic performance. Scotland and more recently Wales have deviated from this practice and have gone down the road of controlling skid resistance by a performance specification. A 2020 report for Transport Scotland by WSP has some encouraging findings on this new approach.